A na-eji microscope eletrọn na-enyocha ihe iji hụ mgbawa ike ọgwụgwụ na nyochaa usoro mgbaji; N'otu oge ahụ, a na-eme nyocha nke ike ọgwụgwụ na-atụgharị na ụdị decarburized na okpomọkụ dị iche iche iji tụnyere ndụ ike ọgwụgwụ nke ígwè ule na-enweghị decarburization, na nyochaa mmetụta nke decarburization na ike ọgwụgwụ nke ígwè ule. Nsonaazụ na-egosi na, n'ihi n'out oge ịdị adị nke oxidation na decarburization na kpo oku usoro, mmekọrịta dị n'etiti abụọ, n'ihi na ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa na uto nke okpomọkụ na-egosi a na-emekarị nke na-amụba na mgbe ahụ ibelata, na. ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa esịmde a kacha uru nke 120 μm na 750 ℃, na ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa ruru a kacha nta uru nke 20 μm na 850 ℃, na ike ọgwụgwụ nke ígwè ule bụ banyere 760 MPa, na isi iyi ike ọgwụgwụ na nchara ule bụ tumadi Al2O3 na-abụghị ọla inclusions; omume decarburization nke ukwuu na-ebelata ndụ ike ọgwụgwụ nke nchara ule, na-emetụta arụmọrụ ike ọgwụgwụ nke nchara ule, nke ukwuu na oyi akwa decarburization, na-ebelata ndụ ike ọgwụgwụ. Iji belata mmetụta nke decarburization oyi akwa na ike ọgwụgwụ arụmọrụ nke ule ígwè, ezigbo okpomọkụ ọgwụgwọ okpomọkụ nke ule ígwè kwesịrị ịtọ na 850 ℃.

Gear bụ akụkụ dị mkpa nke ụgbọ ala, N'ihi ọrụ ahụ na oke ọsọ ọsọ, akụkụ nke meshing nke elu gear ga-enwe ike dị elu na nkwụsị abrasion, na mgbọrọgwụ ezé ga-enwe ezigbo ike na-ehulata ike ọgwụgwụ n'ihi ibu ugboro ugboro ugboro ugboro, iji zere mgbawa na-eduga na ihe onwunwe. mgbaji. Nnyocha na-egosi na decarburization bụ ihe dị mkpa na-emetụta ọkpụkpụ na-ehulata ike ọgwụgwụ nke ihe ndị na-emepụta ígwè, na-eme ka ike ọgwụgwụ na-agwụ ike bụ ihe dị mkpa na-egosi àgwà ngwaahịa, n'ihi ya, ọ dị mkpa iji mụọ àgwà decarburization ma na-atụgharị ike ọgwụgwụ nke ihe nyocha.

N'akwụkwọ a, ọkụ ọgwụgwọ ọkụ na 20CrMnTi gear steel surface decarburization test, nyochaa dị iche iche okpomọkụ okpomọkụ na ule ígwè decarburization oyi akwa omimi nke mgbanwe iwu; iji QBWP-6000J dị mfe beam ike ule igwe na ule ígwè rotary ekwe ike ọgwụgwụ ule, mkpebi siri ike nke ígwè ike ọgwụgwụ arụmọrụ, na n'otu oge ahụ iji nyochaa mmetụta nke decarburization na ike ọgwụgwụ arụmọrụ nke ígwè ule maka n'ezie mmepụta ka mma. usoro mmepụta, welie àgwà nke ngwaahịa ma nye nkọwa ezi uche dị na ya. A na-ekpebi ịrụ ọrụ ike ọgwụgwụ nchara nchara site na igwe nnwale na-agbagọ ike ọgwụgwụ.

1. Nyochaa ihe na ụzọ

Ihe nyocha maka otu unit iji nye 20CrMnTi gear steel, ihe mejupụtara kemịkalụ bụ isi dị ka egosiri na Tebụl 1. Decarburization Test: A na-edozi ihe nyocha n'ime Ф8 mm × 12 mm cylindrical specimen, elu kwesịrị ịdị na-egbuke egbuke na-enweghị ntụpọ. Okpomọkụ ọgwụgwọ ọkụ e kpụ ọkụ n'ọnụ ka 675 ℃, 700 ℃, 725 ℃, 750 ℃, 800 ℃, 850 ℃, 900 ℃, 950 ℃, 1,000 ℃, 1,000 ℃, ndị ikom na jide s. Mgbe ọgwụgwọ okpomọkụ nke ihe atụ ahụ gasịrị site na ịtọ, na-egweri na polishing, na 4% nke nitric acid ngwọta eze mmiri, iji metallurgical microscopy na-ekiri ule ígwè decarburization oyi akwa, na-atụle omimi nke decarburization oyi akwa na dị iche iche okpomọkụ. Nnwale ike ọgwụgwụ na-ehulata: ihe nyocha dị ka ihe achọrọ maka nhazi nke otu abụọ nke ụdị ike ọgwụgwụ na-atụgharị, otu nke mbụ anaghị eme nnwale decarburization, nke abụọ nke ule decarburization na okpomọkụ dị iche iche. Iji igwe na-ehulata ike ọgwụgwụ nke igwe na-anwale igwe, otu abụọ nke igwe nyocha maka ịgbanye ule ike ọgwụgwụ, mkpebi siri ike ike ọgwụgwụ nke otu abụọ nke igwe nnwale, ntụnyere ndụ ike ọgwụgwụ nke otu abụọ nke igwe nyocha, ojiji nke nyocha. eletrọn microscope ike ọgwụgwụ nke eletrọnịnụ, nyochaa ihe kpatara mgbaji nke ụdị ahụ, iji chọpụta mmetụta nke decarburization nke ike ọgwụgwụ nke nchara ule.

Tebụl 1 Ngwakọta kemịkalụ (oke ntakiri) nke igwe nyocha wt%

Mmetụta nke okpomọkụ okpomọkụ na decarburization

The morphology nke decarburization nzukọ n'okpuru dị iche iche kpo oku okpomọkụ e gosiri na Fig. 1. Dị ka a pụrụ ịhụ na ọnụ ọgụgụ, mgbe okpomọkụ bụ 675 ℃, sample elu adịghị apụta decarburization oyi akwa; mgbe okpomọkụ na-ebili na 700 ℃, ihe nlele n'elu decarburization oyi akwa malitere ịpụta, n'ihi na mkpa ferrite decarburization oyi akwa; na okpomọkụ adahade 725 ℃, sample elu decarburization oyi akwa ọkpụrụkpụ mụbara nke ukwuu; 750 ℃ decarburization oyi akwa ọkpụrụkpụ ruru ya kacha uru, n'oge a, na ferrite ọka bụ ihe doro anya, keadighi rarii; mgbe okpomọkụ adahade na 800 ℃, decarburization oyi akwa ọkpụrụkpụ malitere ibelata budata, ya ọkpụrụkpụ dara na ọkara nke 750 ℃; mgbe okpomọkụ na-aga n'ihu na-ebili na 850 ℃ na ọkpụrụkpụ nke decarburization gosiri na Fig. 1. 800 ℃, zuru decarburization oyi akwa ọkpụrụkpụ malitere ibelata budata, ya ọkpụrụkpụ dara 750 ℃ mgbe ọkara; mgbe okpomọkụ na-aga n'ihu na-ebili na 850 ℃ na n'elu, ule ígwè zuru decarburization oyi akwa ọkpụrụkpụ na-aga n'ihu na-ebelata, ọkara decarburization oyi akwa ọkpụrụkpụ malitere nwayọọ nwayọọ na-abawanye ruo mgbe zuru decarburization oyi akwa morphology niile okụrede, ọkara decarburization oyi akwa morphology nwayọọ nwayọọ doro anya. Ọ nwere ike ịhụ na ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa na-abawanye na okpomọkụ na mbụ mụbara wee belata, ihe kpatara nke a onu bụ n'ihi sample na kpo oku usoro n'otu oge oxidation na decarburization omume, naanị mgbe. ọnụ ọgụgụ decarburization dị ngwa ngwa karịa ọsọ nke oxidation ga-apụta ihe ngosi decarburization. Na mmalite nke ikpo ọkụ, ọkpụkpụ nke oyi akwa zuru oke na-abawanye nwayọọ nwayọọ na-abawanye na okpomọkụ ruo mgbe ọkpụkpụ nke oyi akwa zuru oke ruru oke uru, n'oge a iji nọgide na-ebuli okpomọkụ, ihe atụ oxidation ọnụego dị ngwa ngwa karịa. ọnụ ọgụgụ decarburization, nke na-egbochi mmụba nke oyi akwa zuru oke, na-eme ka ọ dị ala. Ọ nwere ike ịhụ na, n'ime nso nke 675 ℃ 950 ℃, uru nke ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa na 750 ℃ bụ ndị kasị ibu, na uru nke ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa na 850 ℃ bụ kacha nta, Ya mere, a na-atụ aro ikpo ọkụ ọkụ nke ígwè ule ka ọ bụrụ 850 ℃.

Fig.1 Histomorphology nke decarburized oyi akwa nke ule ígwè ẹkenịmde dị iche iche kpo oku okpomọkụ maka 1h

E jiri ya tụnyere nke ọkara decarburized oyi akwa, ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa nwere mmetụta ọjọọ dị njọ karị na ihe onwunwe, ọ ga-ebelata nke ukwuu n'ibu Njirimara nke ihe onwunwe, dị ka mbenata ike, isi ike, eyi iguzogide na ike ọgwụgwụ ókè. , wdg, na-amụbakwa uche na cracks, na-emetụta àgwà nke ịgbado ọkụ na na. Ya mere, ịchịkwa ọkpụrụkpụ nke oyi akwa decarburized zuru oke dị oke mkpa iji melite arụmọrụ ngwaahịa. Ọnụọgụ 2 na-egosi mgbanwe dị iche iche nke ọkpụkpụ nke oyi akwa zuru oke na-ekpo ọkụ na okpomọkụ, nke na-egosi ọdịiche nke ọkpụkpụ nke oyi akwa zuru oke nke ọma. Enwere ike ịhụ site na ọnụ ọgụgụ ahụ na ọkpụrụkpụ nke oyi akwa decarburized zuru oke bụ naanị ihe dịka 34μm na 700 ℃; na okpomọkụ na-ebili ruo 725 ℃, ọkpụrụkpụ nke oyi akwa decarburized zuru oke na-abawanye nke ukwuu ruo 86 μm, nke karịrị ugboro abụọ nke ọkpụrụkpụ nke oyi akwa decarburized zuru oke na 700 ℃; mgbe a na-ebuli okpomọkụ ruo 750 ℃, ọkpụrụkpụ nke oyi akwa decarburized zuru oke Mgbe okpomọkụ na-ebili na 750 ℃, ọkpụrụkpụ nke oyi akwa decarburized zuru oke ruru uru kachasị nke 120 μm; dị ka okpomọkụ na-aga n'ihu na-ebili, ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa na-amalite ibelata sharply, ka 70 μm na 800 ℃, na mgbe ahụ na kacha nta uru nke banyere 20μm na 850 ℃.

Fig.2 Ọkpụrụkpụ nke n'ụzọ zuru ezu decarburized oyi akwa dị iche iche okpomọkụ

Mmetụta nke decarburization na ịrụ ọrụ ike ọgwụgwụ na ịgbatị ọkpụkpụ

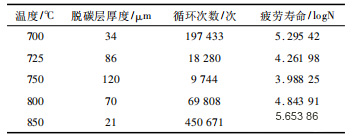

Iji na-amụ mmetụta nke decarburization na ike ọgwụgwụ Njirimara nke mmiri ígwè, a rụrụ ìgwè abụọ nke spine ekwe ike ọgwụgwụ ule, nke mbụ otu bụ ike ọgwụgwụ ule ozugbo na-enweghị decarburization, na nke abụọ otu bụ ike ọgwụgwụ ule mgbe decarburization n'otu nrụgide. larịị (810 MPa), na decarburization usoro e mere na 700-850 ℃ maka 1 h. E gosipụtara ìgwè mbụ nke ihe atụ na tebụl 2, nke bụ ndụ ike ọgwụgwụ nke ígwè mmiri.

A na-egosi ndụ ike ọgwụgwụ nke ìgwè mbụ nke ụdị ihe atụ na Tebụl 2. Dị ka a pụrụ ịhụ site na tebụl 2, na-enweghị decarburization, nchara ule ahụ bụ nanị n'okpuru 107 cycles na 810 MPa, ọ dịghịkwa mgbaji mere; mgbe ọkwa nrụgide karịrị 830 MPa, ụfọdụ n'ime ihe atụ ahụ malitere ịgbaji; mgbe ọkwa nrụgide ahụ karịrị 850 MPa, ụdị ike ọgwụgwụ ahụ niile gbajiri.

Tebụl 2 Ndụ ike ọgwụgwụ n'okpuru ọkwa nrụgide dị iche iche (na-enweghị decarburization)

Iji chọpụta njedebe ike ọgwụgwụ, a na-eji usoro otu ahụ chọpụta njedebe ike ọgwụgwụ nke nchara ule, na mgbe nyochachara data, njedebe ike ọgwụgwụ nke nchara ule dị ihe dị ka 760 MPa; iji mara ndụ ike ọgwụgwụ nke ígwè ule n'okpuru nrụgide dị iche iche, a na-eme atụmatụ SN curve, dị ka e gosiri na Figure 3. Dị ka a pụrụ ịhụ site na Figure 3, dị iche iche nrụgide ọkwa kwekọrọ na ndụ ike ọgwụgwụ dị iche iche, mgbe ndụ ike ọgwụgwụ nke 7. , kwekọrọ na ọnụ ọgụgụ nke cycles maka 107, nke pụtara na ihe atụ n'okpuru ọnọdụ ndị a bụ site na steeti, ọnụ ahịa nrụgide kwekọrọ na ya nwere ike ịdị ka ike ike ọgwụgwụ, ya bụ, 760 MPa. Enwere ike ịhụ na ntụgharị S - N dị mkpa maka ikpebi ndụ ike ọgwụgwụ nke ihe ahụ nwere uru ntụaka dị mkpa.

Ọgụgụ 3 SN akụkụ nke nnwale ike ike ike rotary rotary nnwale

A na-egosi ndụ ike ọgwụgwụ nke ìgwè nke abụọ nke ihe atụ na tebụl 3. Dị ka a pụrụ ịhụ na tebụl 3, mgbe a na-eme ka ígwè nyocha ahụ decarburized na okpomọkụ dị iche iche, a na-ebelata ọnụ ọgụgụ nke okirikiri, na ha karịrị 107, na ihe niile. ụdị ike ọgwụgwụ na-agbaji, na ndụ ike ọgwụgwụ na-ebelata nke ukwuu. Ejikọtara na n'elu decarburized oyi akwa ọkpụrụkpụ na okpomọkụ mgbanwe usoro pụrụ ịhụ, 750 ℃ decarburized oyi akwa ọkpụrụkpụ bụ nke kasị ibu, kwekọrọ na kasị ala uru nke ike ọgwụgwụ ndụ. 850 ℃ decarburized oyi akwa ọkpụrụkpụ bụ nke kacha nta, kwekọrọ na ike ọgwụgwụ ndụ uru bụ dịtụ elu. Enwere ike ịhụ na omume decarburization na-ebelata ike ọgwụgwụ nke ihe onwunwe, na akwa oyi akwa decarburized, na-ebelata ndụ ike ọgwụgwụ.

Tebụl 3 Ndụ ike ọgwụgwụ na okpomọkụ decarburization dị iche iche (560 MPa)

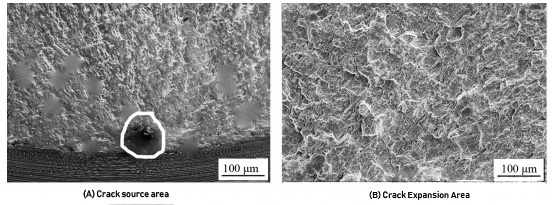

A na-ahụ morphology nke ike ọgwụgwụ nke ụdị ahụ site na nyochaa microscope electron, dị ka e gosiri na Fig. 4. Foto 4 (a) maka ebe mgbape mgbape, a pụrụ ịhụ ọnụ ọgụgụ ahụ doro anya ike ọgwụgwụ arc, dị ka ike ọgwụgwụ arc ịchọta isi iyi. nke ike ọgwụgwụ, nwere ike ịhụ, mgbape isi iyi maka "anya azụ-anya" na-abụghị ọla inclusions, inclusions na mfe ime ka nchegbu ịta, na-akpata ike ọgwụgwụ cracks; Fig. 4 (b) n'ihi na mgbape ndọtị ebe morphology, nwere ike ịhụ doro anya ike ọgwụgwụ n'ọnyá, bụ osimiri-dị ka nkesa, bụ nke quasi-dissociative mgbaji, na cracks ịgbasa, emecha na-eduga mgbawa. Ihe osise 4 (b) na-egosi morphology nke ebe mgbape mgbasawanye, ike ọgwụgwụ doro anya nwere ike ịhụ, n'ụdị nkesa nke osimiri, nke bụ nke quasi-dissociative fracture, na na-aga n'ihu na mgbasawanye nke cracks, n'ikpeazụ na-eduga mgbawa. .

Nyocha mgbawa ike ọgwụgwụ

Fig.4 SEM morphology nke ike ọgwụgwụ mgbaji n'elu nke nnwale ígwè

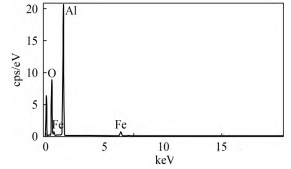

Iji chọpụta ụdị ntinye aka na Fig 4, a na-eme nyocha nke ike ike dị iche iche, a na-egosipụtakwa nsonaazụ ya na Fig. bụ isi iyi nke mgbawa mere site inclusions cracking.

Ọnụọgụ 5 Ike Spectroscopy nke ihe ndị na-abụghị ọla

mechie

(1) Idobe okpomọkụ kpo oku na 850 ℃ ga-ebelata ọkpụrụkpụ nke oyi akwa decarburized iji belata mmetụta na ike ọgwụgwụ.

(2) Oke ike ọgwụgwụ nke nchara nchara nchara na-agbagọ bụ 760 MPa.

(3) Ngwongwo ule na-agbawa n'ime ihe ndị na-abụghị ọla, ọkachasị ngwakọta Al2O3.

(4) decarburization kpọrọ ihe belata ike ọgwụgwụ ndụ nke nchara ule, na thicker na decarburization oyi akwa, ala ike ọgwụgwụ ndụ.

Oge nzipu: Jun-21-2024